The lens of Tilganga in the eyes of citizens of 40 countries

We use Google Cloud Translation Services. Google requires we provide the following disclaimer relating to use of this service:

This service may contain translations powered by Google. Google disclaims all warranties related to the translations, expressed or implied, including any warranties of accuracy, reliability, and any implied warranties of merchantability, fitness for a particular purpose, and noninfringement.

Last Thursday Dr. When he met Sanduk Ruit, there was a kind of swagger in him. His face, which was always cheerful, wore the weariness of serious contemplation. Dr. In Ruit, there is an uproar to create a financially sustainable industry without distributing profits to the laboratory that produces four and a half million lenses annually. The 'labor pains' that a mother experiences while bringing a new life into the world have also gripped her.

Until now, we had kept the lens production lab hidden in the ground floor of Tilganga. But now it has to come out. Must be big. It should be produced more," he said. "Its operation is commercial, but all the profits it makes go to the community. It is sustainable now but not progressing. I think this is a gold mine. Therefore, I believe that the society should take advantage of it by making good use of it.'

Nepal Eye Program, Tilganga Eye Institute's production department 'The Fred Hollows Intraocular Lens Laboratory' is now preparing to be formally transformed into an industry. "We have registered it as an industry that does not distribute profits in the Ministry of Industry of the Government of Nepal," said Dr. Ruit said, "We are establishing this industry in Hetaunda. After that, our production capacity will increase in number, we will be able to compete in the international market by producing different types of premium lenses. Ruit urgently needs around Rs 30 crore to manufacture intraocular lenses in Hetaunda. From where to get that amount, he is confused now. We have completed the registration process at the Ministry of Industry. We have also arranged land in Hetaunda," he said, "However, a lot of money is required until the production process is started after building the infrastructure. It is difficult for an organization that works for the benefit of the community to manage such a large amount at once. Therefore, we want the government to support us. According to him, intraocular lenses are the pride of Nepal. "As the leaders of the country and here call the fast track a project of pride, the lens industry that is planned to be built in Hetaunda is no less than that," he said, "That industry will help Nepal become more known to the world." Such a plan is also a plan of pride!

Photos: Angad Dhakal/Kantipur

Photos: Angad Dhakal/Kantipur

Dr. Ruit says that although the current path is simpler compared to the challenges he faced in the 90s, he is looking for everyone's support to complete this plan. In the 90s, the idea that intraocular lenses could be made in Nepal was difficult in itself. But we did it. The lenses we have produced here have become an environment where citizens of more than 40 countries around the world enjoy them at an affordable price," he said. "This has given us confidence. It has given me the courage to face this challenge. However, we need everyone's support to make it worthwhile.' He thinks that if the lens production industry can be put into operation in Hetaunda, it will open the way for the production of many other types of medical equipment. 'Producing lenses is a technology like producing chips used in any electronic material,' he said, 'We can produce other materials by considering lens production as a standard.' Dr. who did not even think that this journey can be decided in this way till today. Sanduk said. "Even though there was a corner of my mind that intraocular lenses can be made in Nepal one day, I did not think that the journey would be like this," he said, "Despite that, there is no place to complain about the success we achieved." He dedicated to the production of intraocular lenses. He also said that all employees at every level deserve thanks for this success. "The selfless contribution of my colleagues working at Nepal Eye Institute to face every challenge of our journey is appreciable," he said. It is not a success achieved by me alone, it is the result of a collective effort.

Dr. Ruit says that although the current path is simpler compared to the challenges he faced in the 90s, he is looking for everyone's support to complete this plan. In the 90s, the idea that intraocular lenses could be made in Nepal was difficult in itself. But we did it. The lenses we have produced here have become an environment where citizens of more than 40 countries around the world enjoy them at an affordable price," he said. "This has given us confidence. It has given me the courage to face this challenge. However, we need everyone's support to make it worthwhile.' He thinks that if the lens production industry can be put into operation in Hetaunda, it will open the way for the production of many other types of medical equipment. 'Producing lenses is a technology like producing chips used in any electronic material,' he said, 'We can produce other materials by considering lens production as a standard.' Dr. who did not even think that this journey can be decided in this way till today. Sanduk said. "Even though there was a corner of my mind that intraocular lenses can be made in Nepal one day, I did not think that the journey would be like this," he said, "Despite that, there is no place to complain about the success we achieved." He dedicated to the production of intraocular lenses. He also said that all employees at every level deserve thanks for this success. "The selfless contribution of my colleagues working at Nepal Eye Institute to face every challenge of our journey is appreciable," he said. It is not a success achieved by me alone, it is the result of a collective effort.

The history of lens production

dates back to the early 1990s. Dr. Ruit had reached a cataract surgery camp in a village in Nawalparasi. "That's where my friend, well-wisher and in his own words 'soul-mate' Fred Hallows also arrived. Dr. Ruit said, "I performed eye surgery on about 250 people and placed lenses there. Even though he did not operate, he was observing everything going on there.''Dr. According to Ruit, he prepared the necessary instruments for the surgery himself. He used all the skills he knew to make the surgery cheap as well as quality.

dates back to the early 1990s. Dr. Ruit had reached a cataract surgery camp in a village in Nawalparasi. "That's where my friend, well-wisher and in his own words 'soul-mate' Fred Hallows also arrived. Dr. Ruit said, "I performed eye surgery on about 250 people and placed lenses there. Even though he did not operate, he was observing everything going on there.''Dr. According to Ruit, he prepared the necessary instruments for the surgery himself. He used all the skills he knew to make the surgery cheap as well as quality.

At that time, thick glasses were allowed to be worn after cataract surgery. However, instead of glasses, he was engrossed in wearing contact lenses sent by his friends abroad. At that time, many people criticized me for wearing expensive lenses instead of glasses. In Nepal, there was a big belief that contact lenses should not be placed after surgery. It was said that it should not be done in rural areas,' he said, 'I was not discouraged. Keep doing your job.'' He said that he put more emphasis on keeping the lenses because he realized that it was not easy to go about his daily life wearing glasses with thick glass after the operation in the rural environment. At that time, the price of a lens was about 200 US dollars. Because I placed such expensive lenses in the eyes of people living in remote villages of Nepal, I was shocked by many people," he said. "Seeing the results of the camp we did in Nawalparasi, even Fred, who was suffering from kidney cancer, was getting energy. Later Nicole Gratchett, myself and Fred sat down and reviewed it. Everyone was enthusiastic.

Dr. As Ruit recounted the story of his early struggles in life, a hint of satisfaction began to show in the seriousness of his face. The tired face began to radiate energy. According to him, Fred was very enthusiastic at the post-operative review. He was sarcastic to Nicole - "For less than a quarter of the price of an operation, Ruitt is coming here in a rural area and the results are excellent." After listening to Fred, Nicole's question was - "What do you think about such expensive intraocular lenses?" How can you move forward by always asking for help?'

'Fred suddenly said 'we'll make it here' (we'll make it here). I was shocked by what Fred said. The mood suddenly turned serious. But Fred was adamant about his statement, he said, that is, even 15 years ago, it was possible to drive a car without a driver on the road. I was the one who was scared.' It was on that day that the seeds were planted for the establishment of a factory for making intraocular lenses to be put in the eyes after cataract surgery in Nepal. What Fred said at the beginning of the 90s was fulfilled in 1995. However, he did not live to see that factory established. Therefore, this lens manufacturing unit is dedicated to his name - 'The Fred Hollows Intraocular Lens Laboratory,' Dr. Ruit explained, 'The lenses produced by this laboratory have been applied to more than 6.5 million eyes. It is wonderful in itself.

'Fred suddenly said 'we'll make it here' (we'll make it here). I was shocked by what Fred said. The mood suddenly turned serious. But Fred was adamant about his statement, he said, that is, even 15 years ago, it was possible to drive a car without a driver on the road. I was the one who was scared.' It was on that day that the seeds were planted for the establishment of a factory for making intraocular lenses to be put in the eyes after cataract surgery in Nepal. What Fred said at the beginning of the 90s was fulfilled in 1995. However, he did not live to see that factory established. Therefore, this lens manufacturing unit is dedicated to his name - 'The Fred Hollows Intraocular Lens Laboratory,' Dr. Ruit explained, 'The lenses produced by this laboratory have been applied to more than 6.5 million eyes. It is wonderful in itself.

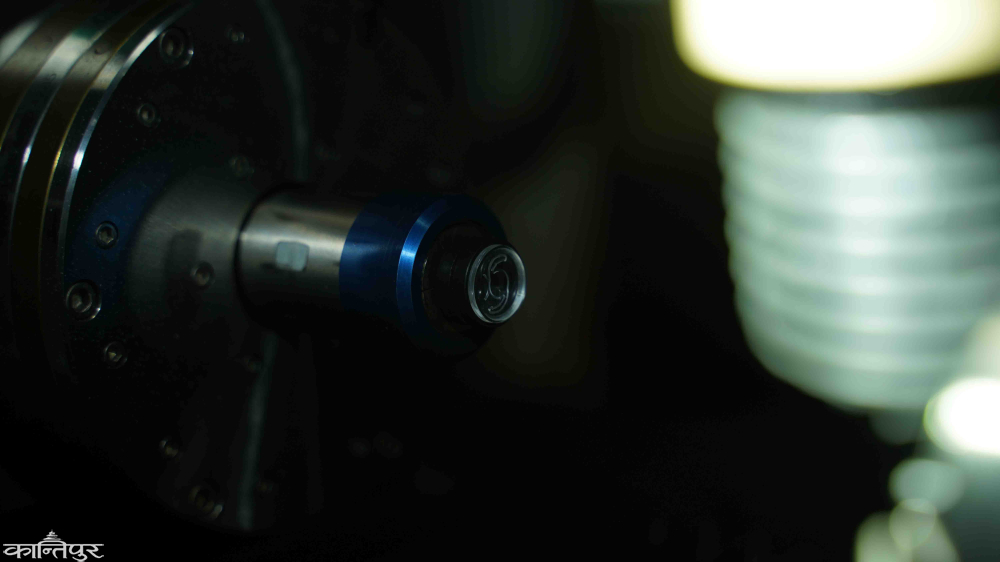

The machine that was installed for the first time did not give the expected results. Ruit said. New things do not progress without any obstacles. That is true," he said. "We learned from it. Then we brought a machine from a company called Lens Tech in Florida, USA. We suffered a lot in 1994-95. He said that there was a shortage of skilled people at that time. We initially started producing 30,000 lenses. After that, we were able to reduce the price of the lens from $200 to $25," he said. "Three years after that, we started producing one hundred thousand lenses. Then the price of the lens came down to less than $6. In this way, we reduced the price of lenses by increasing the number of products.'

The machine that was installed for the first time did not give the expected results. Ruit said. New things do not progress without any obstacles. That is true," he said. "We learned from it. Then we brought a machine from a company called Lens Tech in Florida, USA. We suffered a lot in 1994-95. He said that there was a shortage of skilled people at that time. We initially started producing 30,000 lenses. After that, we were able to reduce the price of the lens from $200 to $25," he said. "Three years after that, we started producing one hundred thousand lenses. Then the price of the lens came down to less than $6. In this way, we reduced the price of lenses by increasing the number of products.'

It is his bitter experience that the world's established multinational companies have given pain when the lenses produced in Nepal started selling for less than 6 dollars. "When we started to push the market of multi-million dollar companies, then they started following us," he said, "even though we worked for the good of not only ours but the world society, they spread negative publicity about us," he wrote. But we are not discouraged.'

dr. According to Ruit, the criticism of the world's established lens companies inspired him to improve the quality of the lenses he produced. "We paid the utmost attention to the production of each and every lens to nullify their criticism," he said. So we went ahead with the belief that every single lens should be of the highest quality. The high quality of every level from raw material to final product has become like a test for us.' According to him, infrastructure is equally important as well as machines and manpower for high quality lens production. "The clean room you see in that production unit is more than one and only," he said. To keep it clean is to keep our product clean.

dr. According to Ruit, the criticism of the world's established lens companies inspired him to improve the quality of the lenses he produced. "We paid the utmost attention to the production of each and every lens to nullify their criticism," he said. So we went ahead with the belief that every single lens should be of the highest quality. The high quality of every level from raw material to final product has become like a test for us.' According to him, infrastructure is equally important as well as machines and manpower for high quality lens production. "The clean room you see in that production unit is more than one and only," he said. To keep it clean is to keep our product clean.

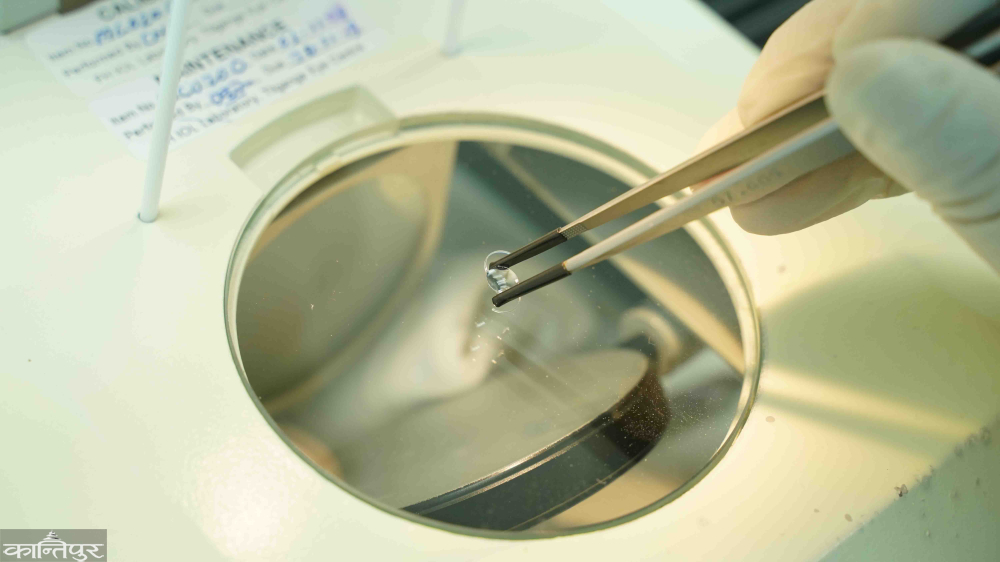

dr. For Ruit, every journey until the lenses produced in Nepal are sent to the world market feels like a movie story. He says that the difficulties he faced at every step helped to make the production of lenses more quality. The lens is of good quality. Then the matter of its verification came up," he said, "Nepal did not have its own verification mechanism. So initially we did ISO certification. Then we also did the CE certification of Europe. Now our lens is also CFDA certified in China.'

Around 13 million people in the world have lost their eyesight due to cataracts. 65 million people are partially sighted due to cataracts. 90 percent of these people live in low-income countries. "If they can be operated on, blindness will be removed," said Dr. Ruit said, 'Our goal is to bring light to them.' According to him, various types of 9-layer intraocular lenses are being produced here. Similarly, three types of materials required for cataract surgery are being produced from the laboratory in the premises of the eye institute in Tilganga.

Around 13 million people in the world have lost their eyesight due to cataracts. 65 million people are partially sighted due to cataracts. 90 percent of these people live in low-income countries. "If they can be operated on, blindness will be removed," said Dr. Ruit said, 'Our goal is to bring light to them.' According to him, various types of 9-layer intraocular lenses are being produced here. Similarly, three types of materials required for cataract surgery are being produced from the laboratory in the premises of the eye institute in Tilganga.

'We manufacture 9 types of lenses. The characteristics of which are different. There are about 22 variants of the same lens,' he said, 'like this, we also make injectors and cartridges as well as capsular tension ring (CTR) needed in surgery.' is "Pakistan, South Africa and China are the main countries to which our products are exported," said Ranjitkar, "During the covid period, exports to China decreased. So we expanded the market elsewhere. Now we are at the final stage for export to Turkey. 40 percent of the lenses produced here are consumed in the Nepali market and 60 percent are exported elsewhere, he said.

'We manufacture 9 types of lenses. The characteristics of which are different. There are about 22 variants of the same lens,' he said, 'like this, we also make injectors and cartridges as well as capsular tension ring (CTR) needed in surgery.' is "Pakistan, South Africa and China are the main countries to which our products are exported," said Ranjitkar, "During the covid period, exports to China decreased. So we expanded the market elsewhere. Now we are at the final stage for export to Turkey. 40 percent of the lenses produced here are consumed in the Nepali market and 60 percent are exported elsewhere, he said.

He says that the Fred Hollows Intraocular Lens Laboratory is currently doing a business worth about 22 million rupees annually. "We are preparing to register it with the Ministry of Industry and make it bigger and bigger," he said. Which will help us to be more established in the international market.'

२६.१२°C काठमाडौं

२६.१२°C काठमाडौं